About Us

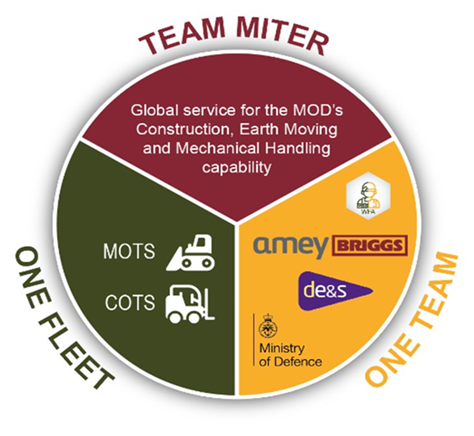

AmeyBriggs is a joint venture between infrastructure support service provider Amey UK Limited and asset management and engineering services provider Briggs Equipment UK Limited.

AmeyBriggs secured the MITER contract to maintain and manage the Ministry of Defence’s (MOD) fleet of construction and materials handling equipment, and other key plant, until 2027.

MITER is an important MOD contract involving the deployment and maintenance of key equipment used by the UK’s Armed Forces around the world as well as supporting military personnel in how to use it. The seven year contract is valued at £240m and brought together three separate contracts under one single fleet management and maintenance provision arrangement.

The Defence Mechanical Handling Equipment (DMHE), Protected Engineering Equipment and C Vehicle capability contracts now form part of the consolidated MITER contract. This supports the MOD’s requirement to ensure a sustained and consistent service for the British Armed Forces personnel on deployed operations at home and overseas.

A major benefit of combining these three contracts into a single contract has been to reduce the overall fleet size and associated equipment costs, whilst continuing to allow the fleet to be modernised.

Vehicles in the MITER fleet include excavators, bulldozers, cranes, and forklift trucks and meet Defence’s need for earth-moving, engineer construction and mechanical handling capabilities.

Fleet Management

AmeyBriggs supports our forces with the supply and full management of their mechanical handling, engineering and construction fleet capability.

AmeyBriggs manage the through life support of the fleet, ensuring there exists a permanent supply chain to provide spares, technical documentation, tooling and testing equipment and training whenever and wherever the Customers need.

AmeyBriggs maintain a high fleet availability to ensure the Customer can respond rapidly and effectively, with confidence that AmeyBriggs can deploy the service quickly if needed.

Equipment

The fleet comprises over 4,000 assets and is a mixture of commercial off the shelf (COTS) and military modified equipment (MOTS), totally balanced to meet MOD capabilities and requirements. The equipment ranges from 50T cranes to 100L concrete mixers, including counterbalance fork trucks and container stackers.

The work horses of the British Armed Forces are the Self-Loading Dump Trucks, Medium Wheeled Tractors, Lighting Towers and Telehandlers. These equipment have been used to great effect, and continue to be, in support of military operations around the globe.

The current fleet, where applicable, will undergo an extensive replacement programme known as the ARP, or a thorough service life extension programme, known as the SLEP.

Some of our best practice services include:

- A bespoke MITER Fleet Information System

- Safety case management and provision of equipment compliant with host nation safety legislation

- Extensive operator and maintainer training

- Whole Force Approach

- Maintenance & repair schedules

- Online and printed technical documentation

Data Exploitation

AmeyBriggs knows that to provide an excellent service to our existing and future customers, it is imperative to have digital technology embedded in what we do. Utilising the latest technology and partnering it with security best practices ensures that AmeyBriggs and our services are functional, safe and agile to deliver value.

By having the right technology and people, AmeyBriggs can analyse our customers’ data to uncover trends and patterns which can then be used to provide better value and a more efficient service.

Our Vision & Strategy

“Through excellence in delivery of MITER, AmeyBriggs will expand, develop and win future contracts”

Our vision sees the business creating a foundation of excellent performance on its core contract, MITER with the MOD, from which we can expand business activity to further contracts with Defence and other customers in the plant and mechanical handling asset management sector.

Our Values

Our Parent Companies

Amey is a leading infrastructure services and engineering company.

They are at the heart of modern Britain, helping the economy to grow by designing, maintaining and transforming the nation’s strategic assets.

Their 11,000 people are behind the critical services the country relies on every day and take personal pride in public service.

Amey’s unique engineering and operations experience, together with data driven insight from their consulting business, delivers better results for their clients.

Amey are trusted partners of Government – both national and local – managing assets and complex projects that are vital to the sustainable growth of the country.

Briggs Equipment is an asset management and engineering services specialist that has transformed the contract hire of industrial machinery.

In addition to being Hyster-Yale Group’s exclusive national distributor in the UK for the Hyster and Yale ranges of materials handling equipment, Briggs enjoys many other strategic partnerships with suppliers that provide industrial cleaning, aerial access, groundworks, agricultural plant and machinery that offer customers a total solution.

Briggs services all the equipment it supplies, with one of the largest teams of mobile engineers across the UK and Ireland. Whether it’s new, used or short-term hire equipment, Briggs has a proposition far more wide-ranging than materials handling.

The company’s market leading fleet management portal plays a pivotal role in driving up standards of customer service and its in-house financing capability, Briggs Finance, offers customers greater flexibility.

Our Health & Safety Commitment

We understand that our everyday operations impact our employees, the communities we work in as well as the global environment. It’s why we’re committed to creating a culture and operating environment that doesn’t simply follow a Safety, Health and Environmental Policy, but pushes for continuous improvement in our performance every day, in every way.

With this in mind, we will continue to:

- Deliver safety excellence through the provision of healthy and safe working conditions, equipment and systems of work

- Avoid, reduce or control the creation, emission or discharge of any type of pollutant or waste

- Work in collaboration with the MOD to optimise its current and future needs

- Ensure the ongoing monitoring, evaluation and continuous reduction of risk

- Involve our employees in the assessment of risk, review of incidents and development of practical controls

- Work closely with our supply chain to reduce risk and apply best practice

- Regularly review performance and strategy at all operational locations through stakeholder feedback, surveys and audits

Health & Safety Management standard 45001 – 2018

Environmental Management standard ISO 14001 – 2015

Quality Management standards ISO 9001 – 2015

Accreditations